One Molecule, Many Applications — and Distinct Requirements

Hyaluronic acid is not a one-size-fits-all molecule. Depending on the target market, the required molecular weight and purity of hyaluronic acid will differ significantly.

- Cosmetic-grade hyaluronic acid (10 kDa–2,000 kDa): used in creams, masks, and dermal fillers

- Nutraceutical-grade hyaluronic acid (1,000–1,500 kDa): used in oral supplements for joint and skin health

- Pharmaceutical-grade hyaluronic acid (500–2,000 kDa): required for ophthalmic solutions, intra-articular injections, and implantable devices

Each of these applications imposes unique demands on the fermentation process. While the cosmetic and nutra segments favor high yields and economic scalability, the pharma segment demands precision, reproducibility, and validated compliance.

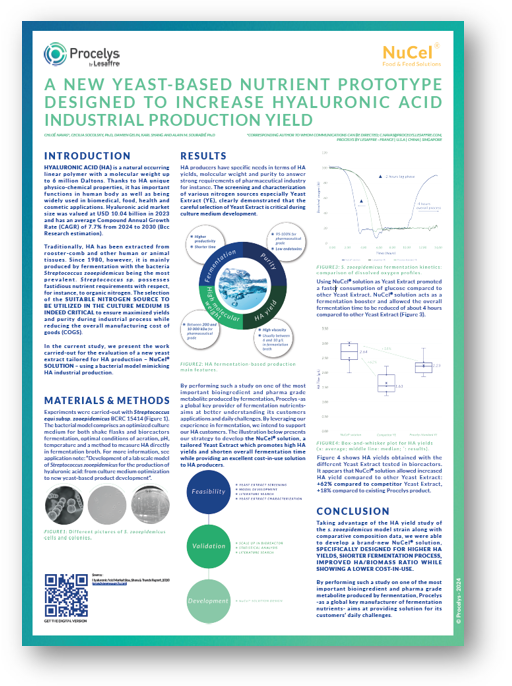

Why Yeast-Based Nutrients are Critical for Hyaluronic Acid Production Success

Fermentation media—and especially the nitrogen source—has a direct impact on hyaluronic acid productivity. Yeast-based nutrients offer a balanced composition of peptides, amino acids, and growth factors essential to microbial strains like Streptococcus zooepidemicus.

Advantages include:

- Consistent biomass-to-metabolite conversion, supporting stable yields

- Improved glucose uptake and fermentation kinetics, leading to shorter batch times

- Simplified downstream processing through clearer broths and lower turbidity

As stated in the scientific application note by Procelys, “the selection of the suitable nitrogen source is critical to ensure maximized yields and purity during the industrial process.”

NuCel® — Growth Rate, Yield, and Nutrient Richness for Cosmetics and Nutra

Fermentation Performance Advantages

NuCel® was developed to help producers boost efficiency while maintaining product quality:

- +62% hyaluronic acid yield compared to standard yeast extract

- -4h fermentation cycle, accelerating time-to-product

- Flexible MW range, ideal for formulations from 10 kDa to 2,000 kDa

These performance benefits translate to tangible economic advantages and are particularly attractive for cosmetic or nutra-grade hyaluronic acid applications.

Composition and Nutrient Profile

NuCel® provides a rich nutrient profile including:

- Free amino acids, peptides, B vitamins, and trace minerals (Zn, Fe, Mg)

- Highly stable batch-to-batch composition for reproducibility

- Animal-free, allergen-free, non-GMO, kosher, halal

While NuCel® meets cosmetic and nutraceutical regulatory standards, it is not designed for pharmaceutical GMP-like validation processes.

ProCel® — Reliability, Purity, and Regulatory Assurance for Pharma-Grade Hyaluronic Acid

Pharmaceutical-Grade Consistency and Compliance

For pharma-grade hyaluronic acid, regulatory compliance and risk mitigation are non-negotiable. ProCel® was developed to align with these requirements:

- Low-endotoxin profiles: essential for injectable/ophthalmic uses

- Validated lot-to-lot consistency: often supported across 3+ lots

- Reinforced documentation and audit readiness: supports regulatory submissions

ProCel® is the better choice for manufacturers seeking to reduce variability and meet EMA or FDA compliance requirements.

ProCel Product Range Contexts

Originally developed for the manufacture of biologics (vaccines, antibiotics, antibodies), ProCel® has a robust quality system and includes:

- Standardized characterization and traceability

- Notification-of-change protocols

- GMP-like manufacturing practices (without formally being GMP-certified)

These features make ProCel® suitable for pharma hyaluronic acid, even when integrated into more complex medical formulations.

NuCel® vs. ProCel® Decision Matrix

Criterion | NuCel® | ProCel® |

Target Applications | Cosmetics, nutraceuticals | Pharmaceuticals (injections, ophthalmics) |

Primary Objective | Maximize yield, reduce fermentation | Ensure purity, compliance, and reproducibility |

Performance Gains | +62% HA yield, -4h fermentation | Validated consistency, optimized purity |

Hyaluronic Acid Molecular Weight | 10–2,000 kDa (flexible) | 500–2,000 kDa (pharma range) |

Endotoxin Control | Standard | Low endotoxin profiles |

Batch Consistency | High, nutrient profiling | Critical, validated (3 lots min) |

Regulatory Compliance | Food/cosmetic grade, clean label | Pharma-oriented, audit-ready |

Still Unsure? Match Your Priorities to the Right Nutrient

Choose NuCel® if you prioritize:

- Faster fermentation cycles

- Higher hyaluronic acid yield at lower production costs

- Formulations for skincare or nutra supplements

Choose ProCel® if you prioritize:

- Batch validation and ultra-low variability

- Low-endotoxin compliance for medical applications

- Regulatory documentation and pharma-grade assurance

Key insight: what you feed your microbes determines not just how fast they grow but what comes out of your reactor.

Beyond the Nutrient — The Procelys Partnership Value

With Procelys, nutrient supply is only the beginning. As part of Lesaffre, the company offers:

- Global technical support from application labs

- Dual sourcing and secured supply chains

- Expert guidance on strain optimization, medium design, and downstream compatibility

Hyaluronic acid producers are not just buying a product. They are gaining a partner who understands the pressure points of industrial biotechnology.

Sources:

- Application note on zooepidemicus HA model development (Procelys, 2019)

- NuCel® and ProCel® product documentation (Procelys, 2023-2025)

- Grand View Research: Hyaluronic Acid Market Size, 2024–2030